HARDWOOD FLOORING INSTALLATION AND REPAIRS

Ready to replace your floors?

Have you been wanting to update your floors? Now is the perfect time to update your flooring. European Parquet Inc. has over 20 years of experience supporting homeowners, general contractors and apartment building management companies throughout the Lost Angeles area with updates to their home and flooring.

Why Install Hardwood in Your Home?

There’s a reason why homeowners have been choosing hardwood as their top flooring choice for decades. It’s an attractive flooring option that allows you a great amount of flexibility with design. While hardwood may not be ideal for rooms with high amounts of moisture (like the bathroom or laundry room), it makes for great flooring in pretty much every other room. Many families have been enjoying their hardwood flooring all-around their homes, from the kitchen to bedrooms.

Engineered Hardwood Flooring

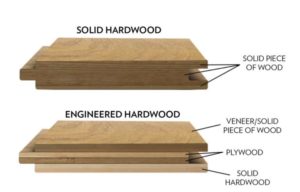

Engineered wood is REAL wood, but instead of one solid piece, it consists of 3 to 10 , plies (thin layers of wood), that are assembled and glued in a cross-ply construction. The top veneer layer of wood can range from .5 mm to 4 mm thick. The industry average is 2 mm thick. Overall board thickness ranges from 1/4″ to 3/4″. Due to its multi-ply structure, engineered wood is much more stable than solid wood and is less susceptible to shrinking and expanding with changes in temperatures and humidity.

Keep in Mind:

• Engineered wood can be installed below ground level as well.

• Engineered wood with a top veneer layer thinner than 2 mm cannot be refinished; however, it can be screened and recoated to renew the surface of the floor.

• Engineered wood with a top veneer layer from 2.5 mm to 4 mm can be sanded.

Hardwood Installation Types

Nail/Staple Down

Hardwood floor installation using the nail down method is usually used for solid wood flooring of ¾” thick strip or plank flooring to a wooden subfloor. Flooring nails are driven down through the tongue of the flooring and sealed securely in the subfloor beneath.

Floating

A floating floor is engineered hardwood that is installed by attaching each board to the next without any conformity to the subfloor. The boards are attached using a bead of glue on the tongue or by a click-together system. Floating floors can even be sanded depending upon how thick the wear layer is.

Glue Down

Glue is predominantly used to link hardwood flooring to fully cured and dry concrete substrates or wood when nailing is just not an option. Glue is used as a sound reducing barrier and can help soften the transfer of noise when hardwood is installed in projects such as apartments, buildings and high rises. Hardwood that is installed with the nail down method may have higher noise transfer between the floors. Always follow the advice of the flooring manufacturer for suggestions on installation.

Nail and Glue Down

In some cases, generally when installing plank flooring 4” and wider, both nailing and gluing the boards is recommended. Always follow the advice of the flooring manufacturer for suggestions on installation.

Types of Flooring

Solid Hardwood Flooring

Solid wood is just that – one piece that is milled from the lumber. It comes in different widths, ranging from 2 1/4″ to 5″ wide and beyond. It also comes in different thicknesses or opacity: 3/4″ is standard, you can even find “thin Profile” solid that is 5/16″ thick.

Keep in Mind:

• Dampness and extreme temperature changes can cause solid wood to diminish and expand, causing gaps between boards during colder and dryer seasons.

• 5/16″ thin profile solid wood can be installed directly over concrete; 3/4″ cannot.

• All solid hardwood flooring can be sanded and refinished if needed (possibly every 15-20 years).

• All urethane coated floors can be screened and recoated as needed to stimulate the surface of the floor. This is less expensive than sanding and refinishing.

• When you order pre-finished hardwood floors, your materials will arrive at your home with a stain and top coat already applied. Unfinished floors (or site finish) will come to your home raw and unfinished. The flooring contractor will apply the finishing layer after installation is complete.